Stratasys, a global leader in additive manufacturing, has ushered in a new era for PolyJet™ technology with the debut of ToughONE™, a material that finally bridges the longstanding gap between visual fidelity and mechanical robustness. Launched on June 10, 2025, ToughONE™ transforms PolyJet from a prototyping tool into a versatile platform capable of producing parts that not only look good—but work—even under real-world stress.

Table of Contents

From Fragile Beauty to Structural Integrity

PolyJet has long been celebrated for delivering vibrant, realistic prototyping with Pantone®-calibrated colours, ultra-smooth finishes, and complex geometries. However, traditional photopolymer resins used in PolyJet have lacked the toughness and impact resistance required for functional testing or end-use part production.

ToughONE™ changes the narrative. Its formulation achieves the highest impact resilience available in the PolyJet family, enabling prototypes that are not only visually stunning but also sturdy enough for real-world validation. With superior shock absorption and wear resistance, it’s ideal for functional trials and small-batch production runs—all without compromising the fine detail and dimensional accuracy PolyJet is known for.

Materials That Mimic Reality

One of ToughONE’s standout features is its ability to emulate a range of commonly used plastics. Depending on curing processes, users can tailor parts to behave like HDPE, PP, PBT, polycarbonate blends (PC‑ABS, PC), Nylon 12, or Nylon 6. This versatility cuts single‑material prototyping costs and simplifies the process of predictive performance modelling.

Additionally, ToughONE™ is TPO-free, reflecting Stratasys’s ongoing efforts to reduce environmental impact.

Built for the J8 Series: Power Meets Precision

ToughONE™ is currently supported across Stratasys’s flagship J8 series: the J826™ Prime, J850™ Prime, and J850™ Pro. These systems offer high-resolution printing, advanced multicolour matching, and proprietary features like Voxel Print™ and Smart Insert™, powered through GrabCAD Print Pro™.

Organizations using earlier models such as the J3 or J5 can now justify upgrades, centralizing design, prototyping, and small‑scale manufacturing on a single platform. New adopters benefit from consolidated workflows—minimizing machine inventory, streamlining processes, and reducing post-processing.

Why It Matters: Faster, Smarter Product Development

1. Accelerate Iterations

With functional-grade prototypes produced in‑house on a single platform, engineers can test form, fit, and durability in record time—dramatically reducing development cycles and time-to-market.

2. Lower Costs

From raw materials and the use of one machine to less labour-intensive post-processing, ToughONE™ helps eliminate cost barriers associated with traditional prototyping, tooling, or low-volume moulding.

3. Boost Product Confidence

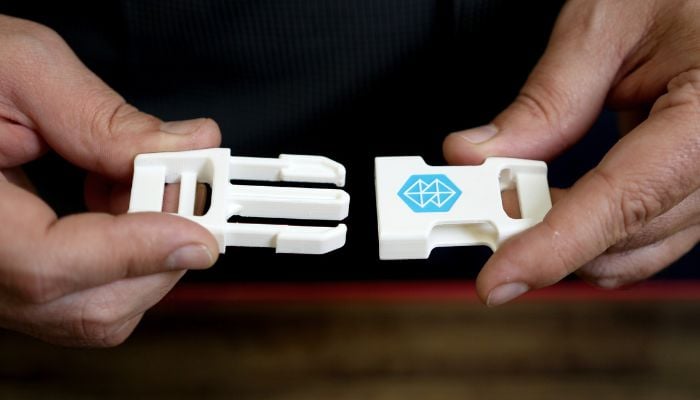

Testing robust parts under real-world stress builds confidence in snap-fits, embedded hinges, housing enclosures, or other load-bearing designs before committing to traditional production.

Key Applications Across Industries

ToughONE™ shines across multiple sectors:

- Consumer Products & Electronics

Ruggedised phone shells, wearables, consumer device enclosures need both sheen and strength. - Automotive

Snap-fit components, trim, and small production parts demand high structural integrity under mechanical load. - Packaging

Functional prototypes for closures, lids, and packaging systems that must endure drop tests and repetitive use. - Medical & Dental

Functional jigs, fixtures, and casings that require both biocompatibility and resilience. - Industrial

Specialized components like electrical connectors, snap-together housings, or heat-resistant parts with high HDT and impact resistance.

Thanks to its compatibility with Stratasys’s multi-material capabilities, designers can also create parts with hard/soft zones in a single build: imagine a rigid housing with integrated flexible hinges or shock-absorbing corners.

Performance Highlights

ToughONE™ offers:

- Impact Resistance: Up to five times greater than typical PolyJet materials.

- High Heat Deflection Temperature (HDT): More suitable for parts exposed to higher temperatures.

- Exceptional Dimensional Precision: Maintains the sub-millimetre accuracy, surface finish, and fine features that PolyJet is known to deliver.

Seamless Integration into Workflows

ToughONE™ slots directly into existing PolyJet workflows:

- Use GrabCAD Print Pro™ to set up jobs with colour, inserts, and varied mechanical zones.

- Choose curing protocols to dial in shore hardness, density, and behaviour.

- Run through standard post-processing—support removal, curing, and finishing—without needing separate tools or systems.

In practical terms, a single engineering department can prototype, stress‑test, finalize mechanical tolerances, and even produce short‑run parts—all in‑house and on the same machine.

What It Means for PolyJet’s Role

Previously viewed as a visual prototyping tool, PolyJet is now fully validated for form + function design. ToughONE™ marks a strategic pivot for Stratasys—redefining PolyJet as an innovation enabler rather than a showcase technology.

This not only elevates its value for companies needing streamlined workflows but also positions Stratasys as a single-source provider across the prototyping‑to‑production continuum.

What’s Next for ToughONE™?

Stratasys has already signalled ongoing development: expect continued research into curing processes, improved Shore range, or new compatible machine releases. Potential enhancements include broader mechanical tuning, greater heat resistance, or mimicking high-performance engineering plastics.

Reliable third-party evaluations are still emerging, but initial assessments show ToughONE™ meeting or exceeding internal claims on impact testing and structural hardness—good news for engineers seeking real-world performance.

Final Take

ToughONE™ isn’t just a new material—it’s a paradigm shift for PolyJet. Stratasys has provided a compelling answer to long-standing designer and engineer challenges: create prototypes that look beautiful and endure reality, all without swapping machines or materials.

By enabling functional strength in full-colour, high-resolution prints on J8 systems, ToughONE™ could streamline innovation cycles, reduce costs, and make high-performance, small-batch manufacturing a reality for more businesses.

Curious to explore ToughONE™? Visit Stratasys to download datasheets, request quotes, or learn via stress‑test videos and application demos.

Join Our Social Media Channels:

WhatsApp: NaijaEyes

Facebook: NaijaEyes

Twitter: NaijaEyes

Instagram: NaijaEyes

TikTok: NaijaEyes